What we do | EXPERTS IN STAINLESS STEEL, STEEL AND ALUMINUM

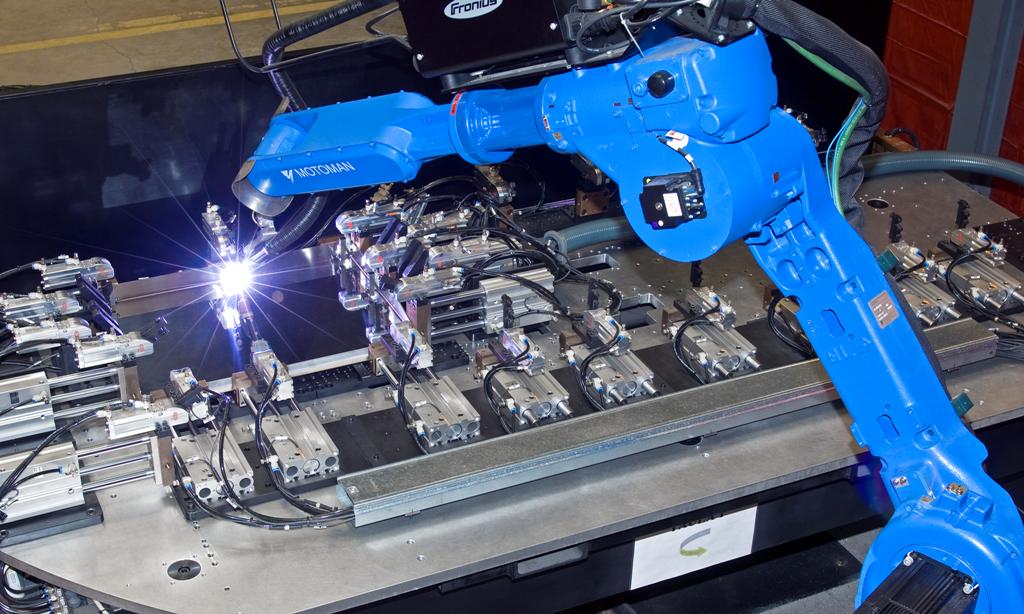

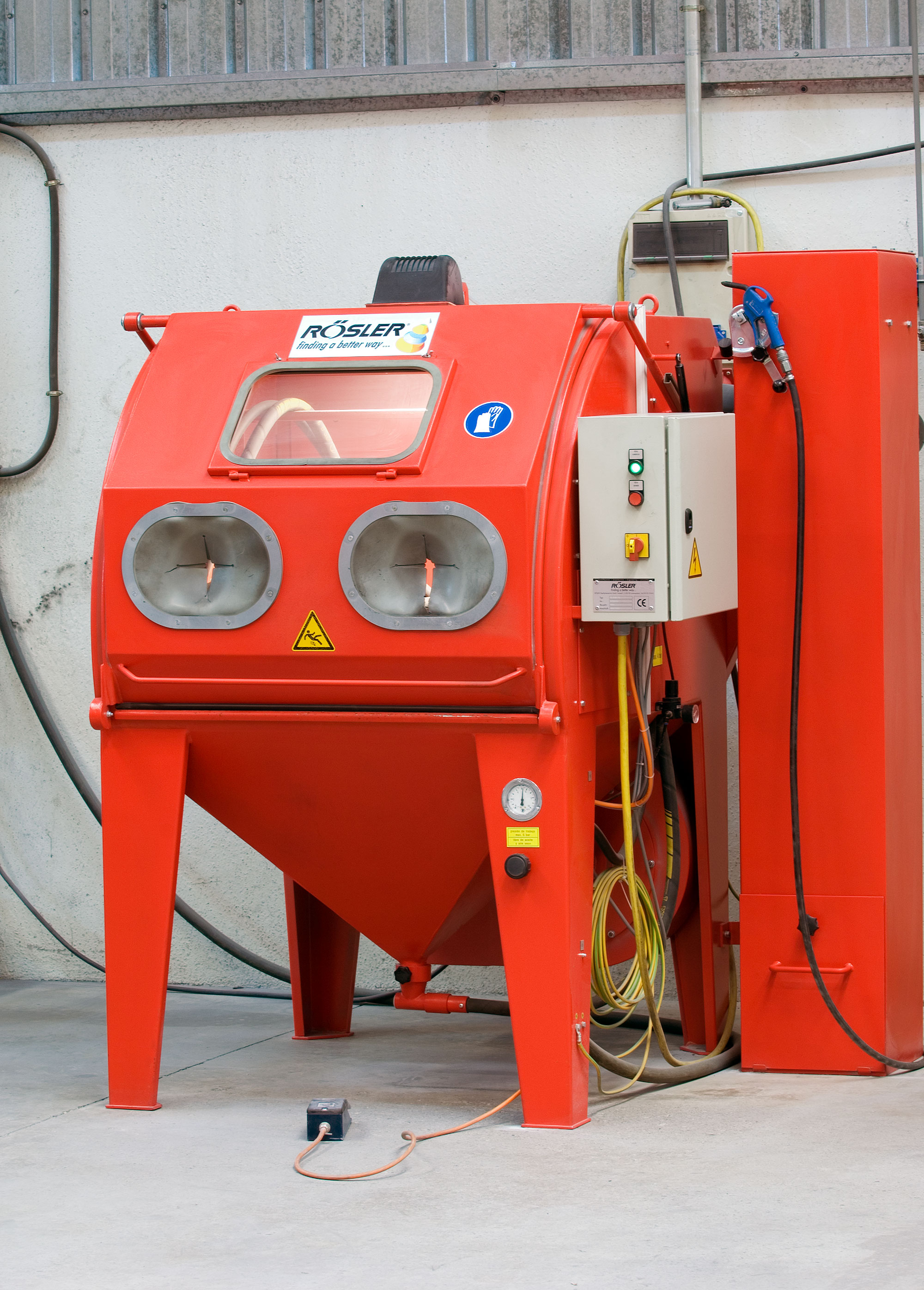

Cut, punching, folding, CNC, wrenching, welding, etc…

We perform a complete production process, from flat plating going through all processes of laser cutting, punching, folding, industrialization, welding, treatment and final finishing touches, as well as assembling and pre assembling all kinds of components, including the packing and palletizing all characteristics and personalized logos from our clients.